- PCB Layout&Design

- Top ten common problems with PCB copy board

- The Difference between Footprints and Land Patterns

- Exclusive Layout Tips for BGA Chips

- Top 10 Best PCB Design Tools

- How to Generate the Gerber Files

- Getting Started with High-Speed PCB Design, Beginners Mus...

- The Best Suited Naming Patterns for PCBs

- How to Export Eagle PCB to Gerber Files

- How to Make Panelized PCB in AlTIum Designer?

- How to Export Altium PCB to Gerber Files

- The Method to Generate Centroid File and BOM from KiCAD

- Half-bridge DC/DC Power Supply Based on LM5036

- How Do We distinguish the DC Resistance and Dynamic Resis...

- The Method to Export KiCAD PCB Design to Gerber Files

- Generating Centroid File and BOM from Altium

- How can Engineers Avoid Inflows During PCB Design

- Signal Reflection in PCBs

- Analyze and Restrict Impedance of High-Speed High Power PCB

- How to Use PCB Layered Stackup to Control EMI Radiation

- Flyback Power Module Circuit Design using ATX Supply

1. Altium Gerber Files

RS-274-X Gerber file format is a defacto data sharing standard for PCB manufacturing. This is basically a printer or plotter language which is used for PCB CAM (Computer Aided Manufacturing) data generation. Almost everyone who uses Altium Designer software for PCB design, either hobbyist or commercial designer, may have used this feature. It is actually a 2D ASCII file format.

Gerber Pcb Design

Gerber file format is evolved from applications where it is used to re-create images or graphics i.e., printers and plotters industry. In the same way it is used in electronics hardware industry to print PCB tracks, vias, pads, text, holes, clearances and all information which is contained in a *.PcbDoc design file. The Altium Designer software tool has a feature to create and gerbtool option to verify data as well.

Pcb Artist Gerber Files

Like other softwares outputs the Altium Designer gerber file can be divided into four subparts:

Right-click a file with the extension whose association you want to change, and then click Open With. In the Open Withdialog box, click the program whith which you want the file to open, or click Browseto locate the program that you want. Select the Always use the selected programto open this kind of file check box. GerbMagic is a free Gerber viewer software with various viewing options available. After clicking, will open the Gerber generate dialog: You can calculate the price for the PCB order, click SAVE to CART will go to JLCPCB and add your PCB in the cart.

How to Design a Simple PCB Gerber File: Seeed Fusion Service are going to launch an activity. People who follow this instruction to design a PCB gerber file and send their gerber file to us can participant in this activity. We will put the gerber on our Fusion Gallery. If yourgerber file. File extension gbr is related to files in a Gerber Format used in PCB industry. A Gerber File is a file format used by printed circuit board manufacturing machines to layout electrical connections such as traces, vias, and pads (the component footprints on the PCB).In addition, the file contains information for drilling, and milling the completed circuit board.

- Configuration Parameters

- Aperture Definitions

- Drawing Commands

- X/Y Coordinates

Each file extension denotes a specific layer such as:

Top Layer => *.gtl

Bottom Layer => *.gbl

Keepout Layer => *.gko

TopOverlay Layer => *.gto

Gerber Pcb Software Free

BottomOverlay Layer => *.gbo etc.

2. Generating Gerbers in Altium Designer

Add layer stackup to any of the mechanical or other suitable layer.

Add other information like manufacturing notes, dimensions, cutouts etc., before generating gerber files.

In Altium Designer it is very easy to setup Gerber Files creation setup. It is done by two ways:

Generate through File>Fabrication Outputs> Gerber Files

It opens Gerber Setup dialogue box.

In Gerber setup dialogue box Set file producing unit system.

In layers pane add layers to be re-produced in gerber format.

In drill drawing pane click plot all used layer pairs on both of the boxes.

Set apertures box.

Set advanced parameters in advanced pane or otherwise keep default settings.

Click ok , it generates the gerber outputs in the project folder.

On same method NC drill files are created i.e., File>Fabrication Outputs> NC Drill Files and then adopt the same steps as above.

Or in other way it can be generated by following steps:

Output Job File to project > Fabrication Outputs> Gerber Files and then set path for files.

Double click 'Gerber Files' it will open Gerber setup. Use the same steps as above and click ok.

Enable output generate option and set target folder location.

How To Open Pcb Gerber Files

Clock Run or double click over generates content. The gerber file outputs will be generated.

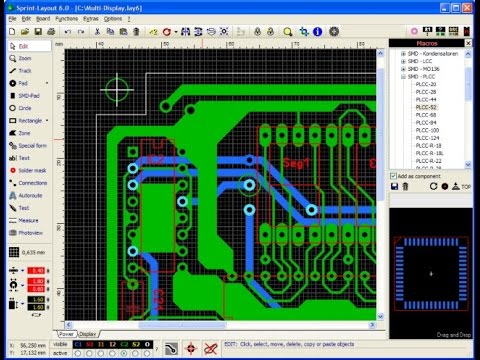

Figure 1: Sample PCB Design file

In figure 1 different layers names are shown in their respective layer. The same layers can be viewed in the final view Figure 5 as Gerber output generated.

Figure 2: Gerbers Settings Dialogue Box

Figure 3: Gerber Setup Dialogue Box opens

Figure 4: Gerber Files generated and viewed in CAMTastic Bottom Layer view

Figure 5: CamTastic complete PCB view

3. What is Needed by Manufacturer

In a gerber file following layers and information should be added:

- 1- Enable all signal layers which have been used for routing in PCB design or those which have electrical signals routing should be enabled to re-produce in gerber format.

- 2- Enable all plane layers which are solid copper and distribute power to the circuit on PCB. These are printed as negative image of layer.

- 3- Enable Keepout layer, it is usually electrical boundary of the board. The keepout can also be asked to manufacturer for cutting boundary.

- 4- Enable required mechanical layers in gerber setup. A mechanical layer does not have any electrical information like in signal layer or plane layers. However, they can have some information about mechanical parameter like PCB cutting or, 3D PCB footprints information, assembly and fixing in enclosures etc.

- 5- Enable Top Overlay and Bottom Overlays which have information of components designators and PCB name, number, nomenclature debug information and test signal details etc.

- 6- Dimensional Information: PCB Dimensions information should be added on top overlay or mechanical or keepout layer of PCB design file before generating gerber files.

- 7- Layer PCB stackup: Before generating gerber files add layer stackup information in any enabled mechanical layers so that manufacturer can use information about PCB material such as base material thickness, pre-preg thickness type etc.

- 8- Preferably produce time and date stamped Gerber files so that they would be back traced for any query.

- 9- Recheck and verify the file types using any gerber viewer software tool.

- 10-If found accurate and forward to the manufacturer.

Figure 6: Gerber files enable and disable and extensions

Figure 6 shows the gerber files produced by Altium Designer software, produced time, type of layer etc.

3. Summary:

Gerber format is RS-274-X 2D ASCII file format. The gerber file format is a defacto standard of interface between a PCB Design engineer and manufacturer. It includes all conductive, mechanical, text and keepout layers information of a PCB design alongwith necessary notes for manufacturing.

The Altium Designer software produces RS-274-X format Gerber files by different methods. The latest software and updates about files generation are available on Altium ®. In this tutorial a complete yet comprehensive guide has been provide.

Next Post: How to Make Panelized PCB in AlTIum Designer?

Introduction: How to Generate Gerber Files From Eagle 9

In this instructable I'm gonna show you how you can generate gerber files from Eagle CAD version 9 and above and how to order your PCBs using the gerber files.

Step 1: Watch the Video!

The video describes the process of generating gerber files using EagleCad and provides info how to use my CAM processor file that will automate the process for you. The are subtle things which are present in the video that we're left out from this instructable for the sake of simplicity.

Step 2: The CAM Processor

The actual start might depend on the cad software that you use for designing pcb’s, in my case that’s Eagle Cad. After finishing up the design of a PCB, you will have to generate the gerber files needed to place your order. Think at these as an universal set of files, stored in a format that every pcb manufacturing facility can read and use to manufacture your pcb exactly as you designed it.

In Eagle CAD we have the CAM processor that takes care of these things, and luckily you can just load a pre-made CAM job file, that will instruct eagle how to output a complete set of gerber files. I have a custom made, voltlog CAM job file for 2 layer pcbs, Here is a link that you can use to download it.

This cam job file will generate all the required gerber files for ordering your pcb, including files for the cream layer which can be used to order a steel stencil that will make assembly of surface mount components much easier. Just click process job and save the resulting zip archive.

Step 3: Verifying the Gerber Files

It’s a good idea to now check your gerber files to see if they look like you want them to look. I often catch problems in the gerber files, things that we’re too small to notice in the pcb layout software. There are a bunch of different website where you can view gerber files online and also a whole set of programs which you can use to do that locally on your computer. Here is one example of an online gerber viewer.

Step 4: Order Your PCB

The next step is to send these files to the pcb fab house and the service I use is JLCPCB.com, they really offer cheap pcbs so ofcourse I’m using their service. At a cost of $2 for a set of 10 pcbs and $6 for a laser cut steel stencil, I don't think you can find cheaper.

The ordering process is as simple as uploading the zip archive with the gerber files we created earlier to their website and going with the default settings. If you are a more advanced user you might play with the settings for getting a different thickness or a different soldermask color for example, but for a beginner, the defaults are good enough and depending on which shipping method you choose in a week (for DHL) you should have the PCBs at your door.

So, that was all, I hope this instructable was useful if so please leave a comment or hit the like or dislike button to send me some feedback.

Be the First to Share

Recommendations

Make it Glow Contest

First Time Author Contest

PCB Challenge